1. The pump adopts double shell structure, some parts are SX series general, bearing rotor is SV series general;

2. The discharge direction of the pump can be changed every 45° and can be installed in eight different directions according to needs;

3. The impeller is specially designed with a special guide blade to maximize the suction and discharge of foam mud;

4. The mobile parts are made of various types of metal materials and have good wear resistance and corrosion resistance.

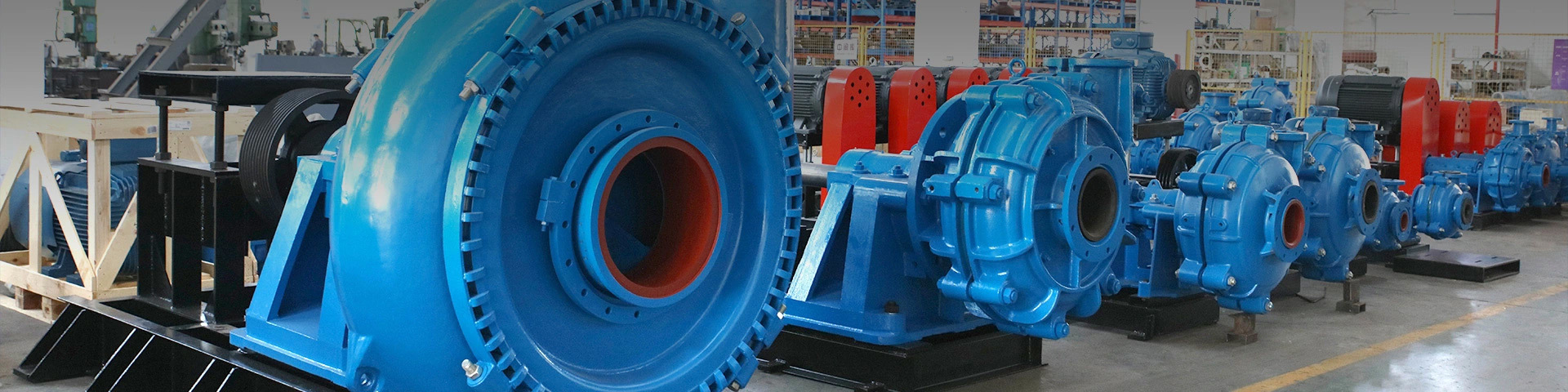

The company's main products include a full range of mud pumps, desulfurization and denitrification FGD project special pumps, sand and gravel pumps, dredging pumps, foam pumps, chemical process pumps, PU rubber mud pumps and other dozens of varieties, hundreds of models, widely used in mining (beneficiation), metallurgy, coal, electricity, flue gas desulfurization, desilting, irrigation, etc. Water conservancy engineering, petroleum, chemical industry, municipal, environmental protection, sewage treatment and other industries.

The total designed production capacity of the company is 10,000 units (sets) per year, and the annual production of all kinds of high chromium alloy castings is 2000 tons. The production area currently consists of five production areas and two centres, namely casting, heat treatment, machining, metal forming and welding, assembly and coating areas; Finished parts warehouse; Quality inspection and analysis, as well as integral hydraulic testing center.