SAF Series Foam Pump

Keywords:

Classification:

Foam Pump

Product details

Product characteristics

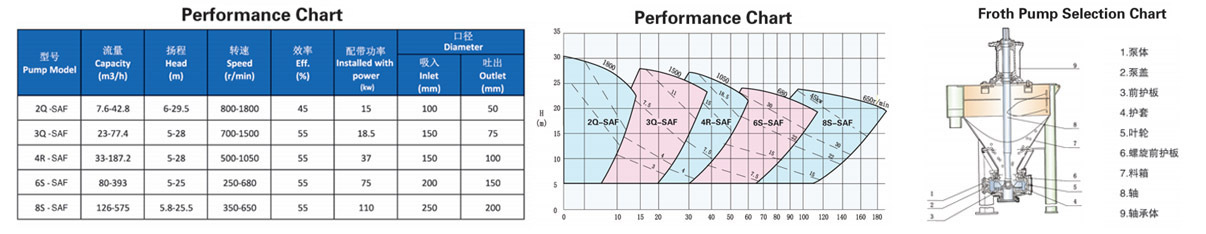

SAF series foam pump is a new generation of products developed and promoted by our factory on the basis of absorbing and digesting advanced technology at home and abroad. It is widely used in metallurgical coal, chemical industry and other industrial sectors. Suitable for conveying abrasive or corrosive slurry containing foam, this series of pumps can effectively eliminate foam in the slurry during operation. It can still work normally in the case of insufficient incoming materials, especially suitable for various flotation processes, and is an ideal product for conveying foam slurry.

Structural characteristics

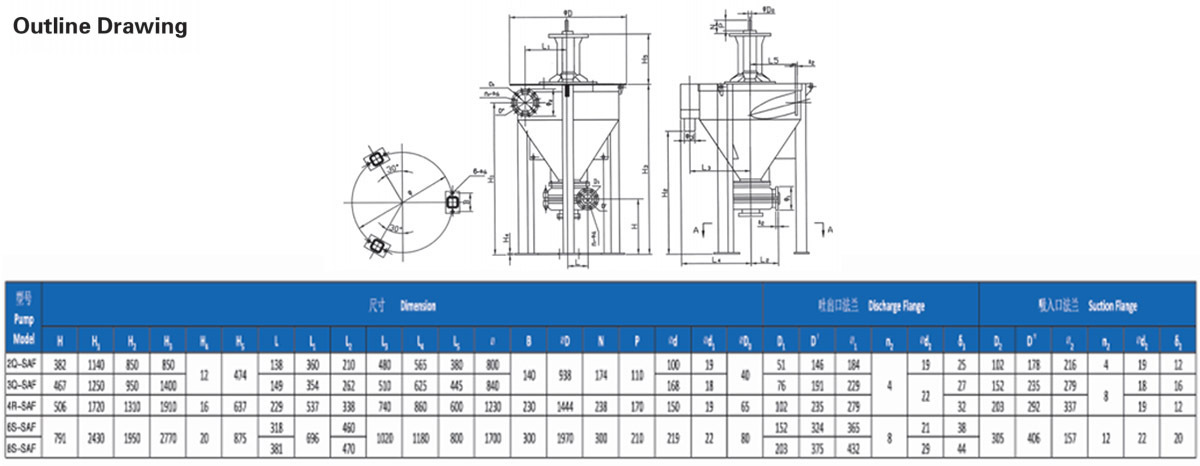

1. The type of pump adopts SVC,SVC(R) type bearing assembly, bearing body is installed with a motor base or electric frame, you can use direct transmission or indirect transmission, you can easily replace the pulley, used to change the speed of the pump to meet the changes in working conditions.

2. The material box is made of steel structure or stainless steel, steel lined with rubber, etc., with tangential inlet and overflow box, overflow box can facilitate the excess incoming material to be returned to the material pool, tangential inlet can make the material quickly enter the pump and eliminate part of the foam.

3. The pump head structure is double pump shell structure, according to the different conveying medium, the flow parts can be used: metal, rubber or other non-metallic materials.

Recommended Products

SX(R)/SH/SM(R) Series Slurry Pump

SPH Series Heavy Duty Slurry Pump

SH Series Heavy Duty Slurry Pump

Product Consultation

If you are interested in our product, please leave your email and we will contact you as soon as possible. Thank you!