SPL Series Slurry Pump

Keywords:

Classification:

Heavy Duty Slurry Pump

Product details

Features and uses

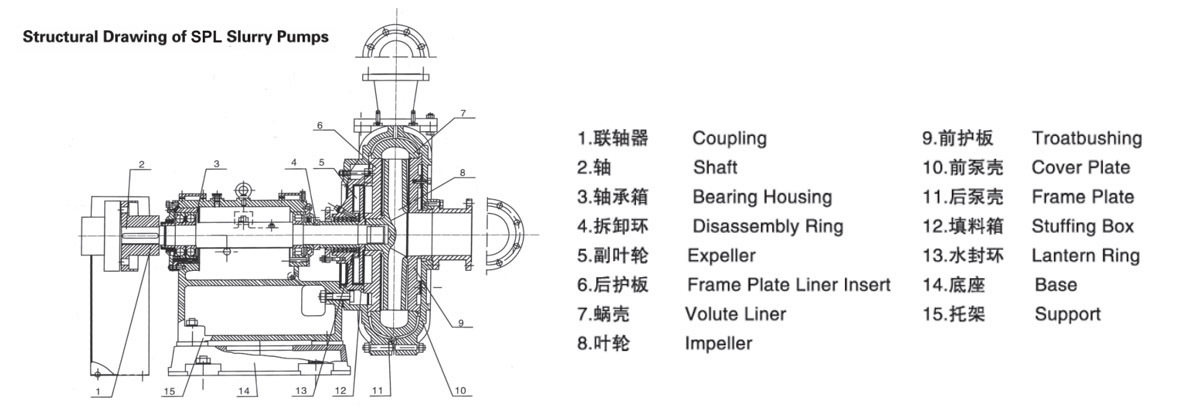

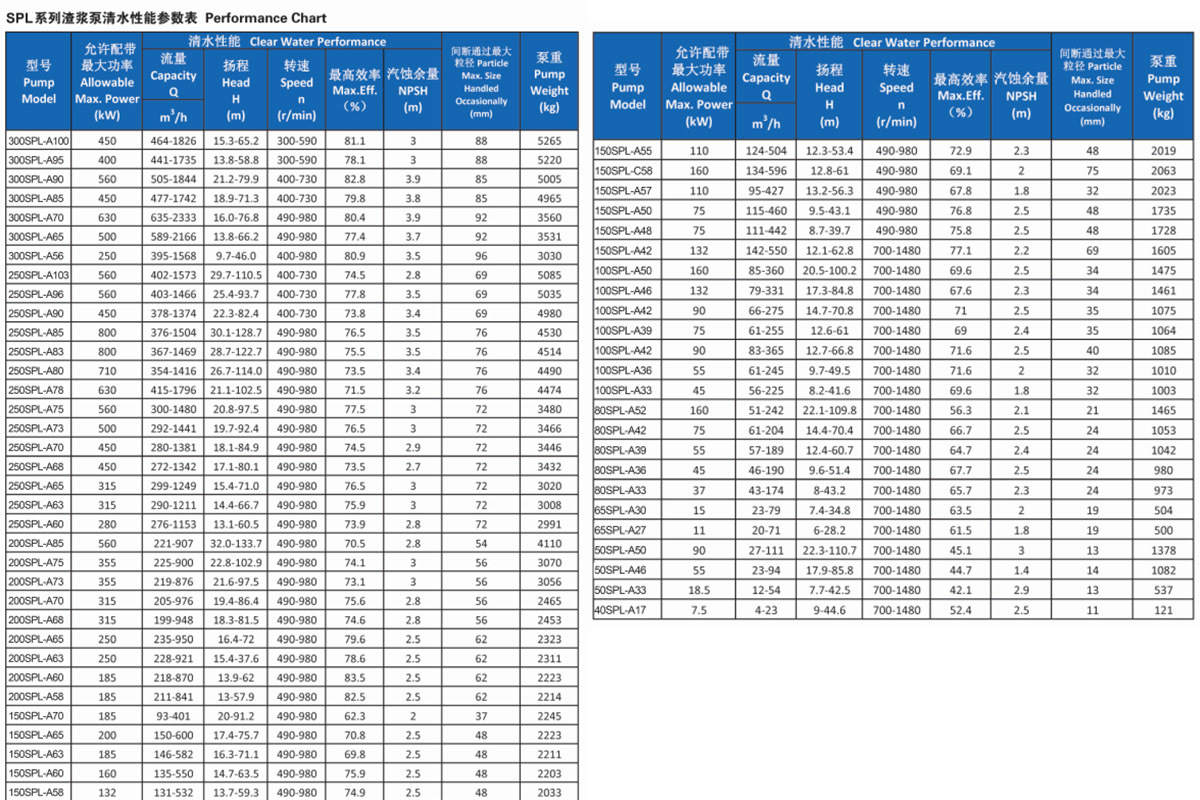

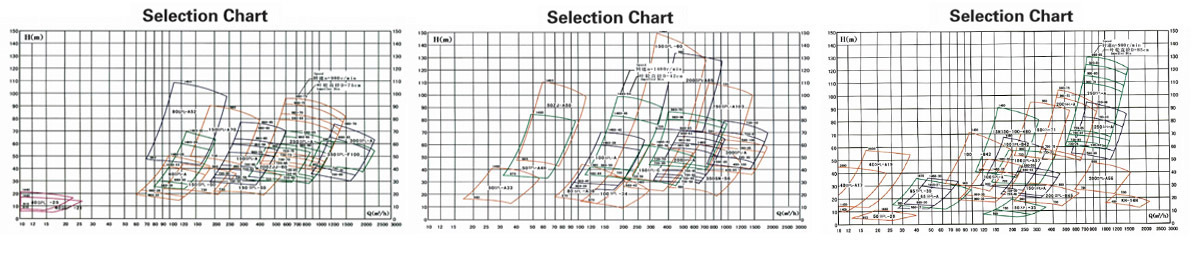

The SPL type slurry pump is a single-stage, single-suction, centrifugal slurry pump designed by our factory. The flow-passing parts of this series of pumps are made of high-hard alloy cast iron, which has high abrasion resistance, corrosion resistance and impact resistance, thus extending the service life of the pump. The pump is divided into horizontal type (SPL series) and vertical type (SPL series) according to its structure. Horizontal pumps are divided into various specifications according to the outlet diameter: 350mm, 300mm, 250mm, 200mm, 150mm, 100mm, 80mm, 65mm, 50mm, 40mm, etc.; each size of pump has different impeller diameters to choose from according to different lifts. This pump is suitable for industrial industries such as electric power, metallurgy, coal, building materials, and chemicals. It is mainly used to transport abrasive slurries containing solid particles, such as processing concentrates and tailings in mineral processing plants, ash removal in power plants, and transportation in coal preparation plants. Coal slime and heavy media coal preparation, slurry transportation in coastal river mining operations, etc. The maximum weight concentration of the slurry it can handle is 45% mortar and 60% slurry; the transmission can be in the form of direct connection, belt, hydraulic, frequency conversion speed regulation, etc. It can also be operated in series or parallel according to user needs.

Sealing form:

SPL series slurry pumps can adopt two shaft seal forms: combined impeller plus packing seal and mechanical seal.

(1) Auxiliary impeller dynamic seal: The auxiliary impeller seal uses the pressure seal generated by the impeller and the associated auxiliary impeller, and the packing or lip seal is used as a parking seal. This sealing form is used for single-stage pumps or multi-stage first-stage pumps in series when the positive pressure value at the pump inlet is not greater than 10% of the pump outlet pressure value. It can operate without shaft seal water, does not dilute the slurry, and has good sealing effect. But it will consume power (generally about 5% of the shaft power).

(2) Packing seal is a common form of shaft seal, suitable for various working conditions. It can be matched with special materials such as polytetrafluoroethylene packing and graphite packing, and can be used under corrosive or high temperature conditions. It has the advantages of simple structure and convenient maintenance.

(3) Mechanical seal: Using internationally leading sealing technology, the sealing effect is good. The modular structure makes installation and replacement easy, and different structural forms are suitable for different working conditions. The friction material is made of high-hardness ceramic and alloy materials. The design and coordination of the mechanical seal and sealing box conform to the flow state of the medium, so it has high wear resistance and shock resistance, and can ensure customer satisfaction under various harsh working conditions.

Recommended Products

SX(R)/SH/SM(R) Series Slurry Pump

SPH Series Heavy Duty Slurry Pump

SH Series Heavy Duty Slurry Pump

Product Consultation

If you are interested in our product, please leave your email and we will contact you as soon as possible. Thank you!