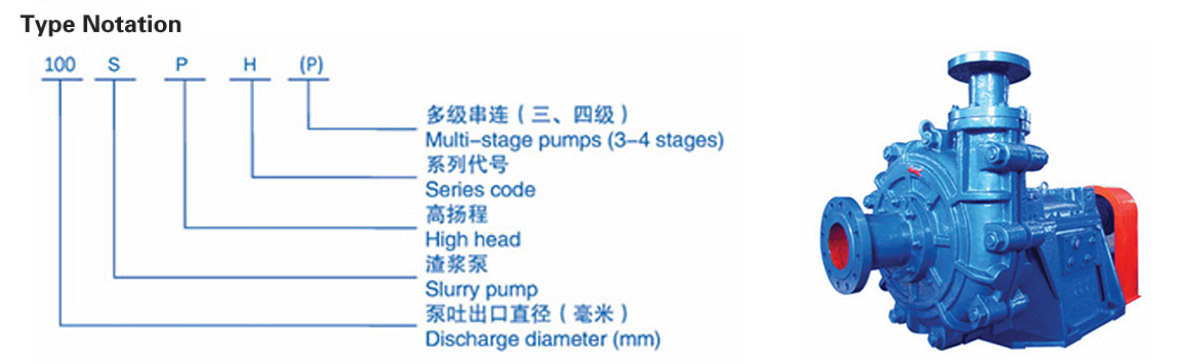

SPH Series Heavy Duty Slurry Pump

Keywords:

Classification:

Heavy Duty Slurry Pump

Product details

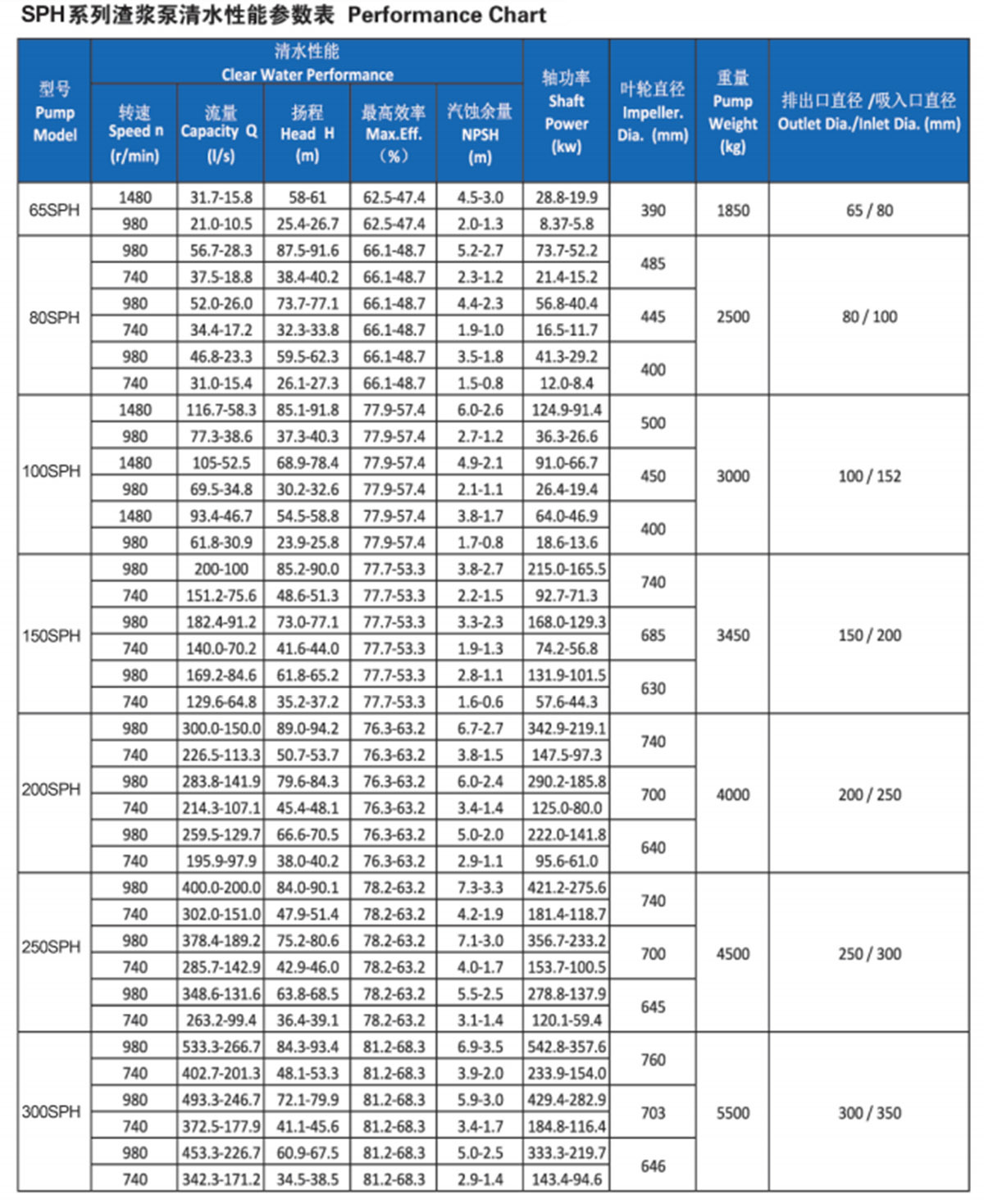

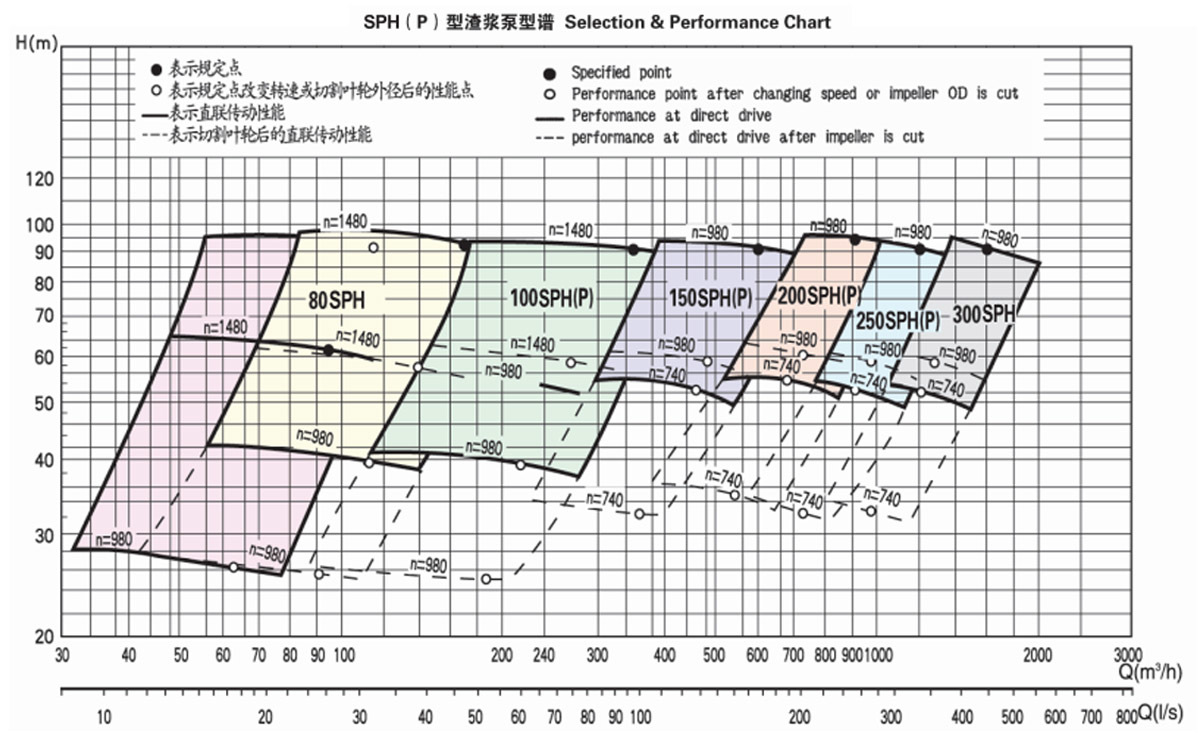

Caliber: 65~300mm; Flow: 50~1900m3/h; Lift: 40~94m

Applicable working conditions:

High-concentration slurry transportation in non-ferrous metal mineral processing, alumina production, coal, electric power, chemical industry and other industries

Structural features:

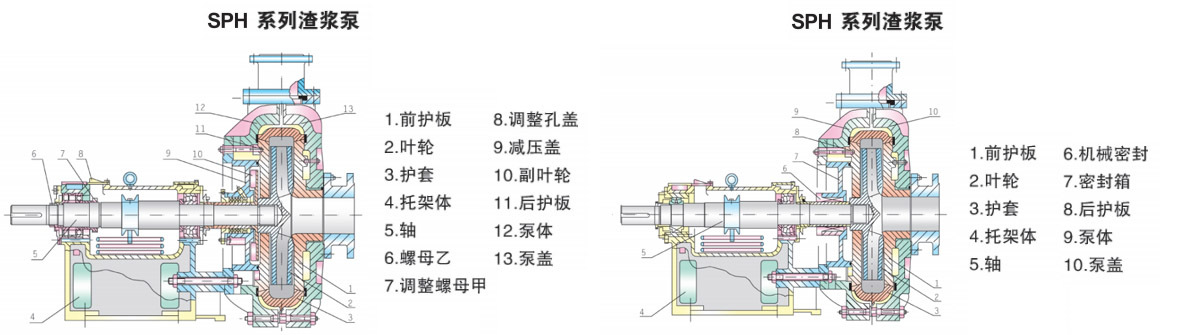

Horizontal, single-stage single-suction, cantilever, double pump casing;

Large flow, high lift, can be used in multi-stage series, different industrial and mining conditions, long-distance transportation horizontally open type thin oil bracket, the bracket has two sets of internal and external cooling systems, lubricating oil self-circulation cooling system;

Some pump models can be equipped with rubber-lined sheaths.

In order to meet the needs of electric power, metallurgy, coal and other industries, and based on the characteristics of ash and slag removal and slurry transportation conditions, based on decades of design and manufacturing of slurry pumps, we have extensively absorbed advanced domestic and foreign technologies and research results. Our factory has The latest generation of SPH(P) series slurry pumps with large flow rate, high lift, and multi-stage series connection.

The main technical features of this series of products are as follows:

Using modern CAD design, it has excellent water conservancy performance, high efficiency and low wear rate; wide flow channel, good anti-clogging performance and superior cavitation performance;

The combination seal and mechanical seal of the auxiliary impeller and packing are used to ensure that the slurry does not leak; the reliability design ensures that the mean time between failures (MTBF) of the entire machine is greatly improved;

Thin oil is used to lubricate metric bearings, and the lubrication and cooling systems are reasonably set up to ensure that the bearings operate at low temperatures: the flow-passing parts are made of special materials with good wear resistance and corrosion resistance;

After special treatment, it is used for seawater ash removal and electrochemical corrosion conditions of seawater and salt spray;

It can be used in multistage series within the allowed pressure range, and its maximum allowable working pressure is 3.6MPa. The series slurry pump products have the advantages of reasonable structure, high efficiency, reliable operation and easy maintenance, etc., widely used in electric power, metallurgy, mining, coal, building materials, chemical industry and other industrial sectors to transport abrasive or corrosive slurry, characterized by power plant ash.

Recommended Products

SX(R)/SH/SM(R) Series Slurry Pump

SPH Series Heavy Duty Slurry Pump

SH Series Heavy Duty Slurry Pump

Product Consultation

If you are interested in our product, please leave your email and we will contact you as soon as possible. Thank you!