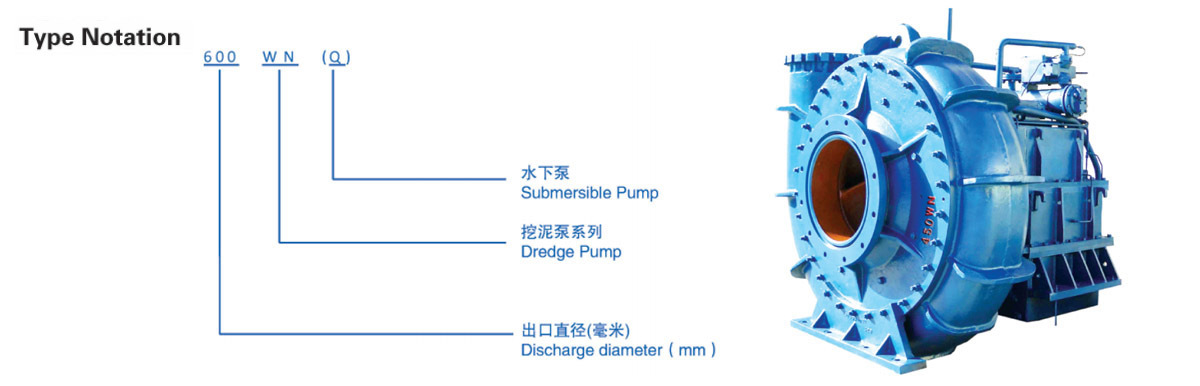

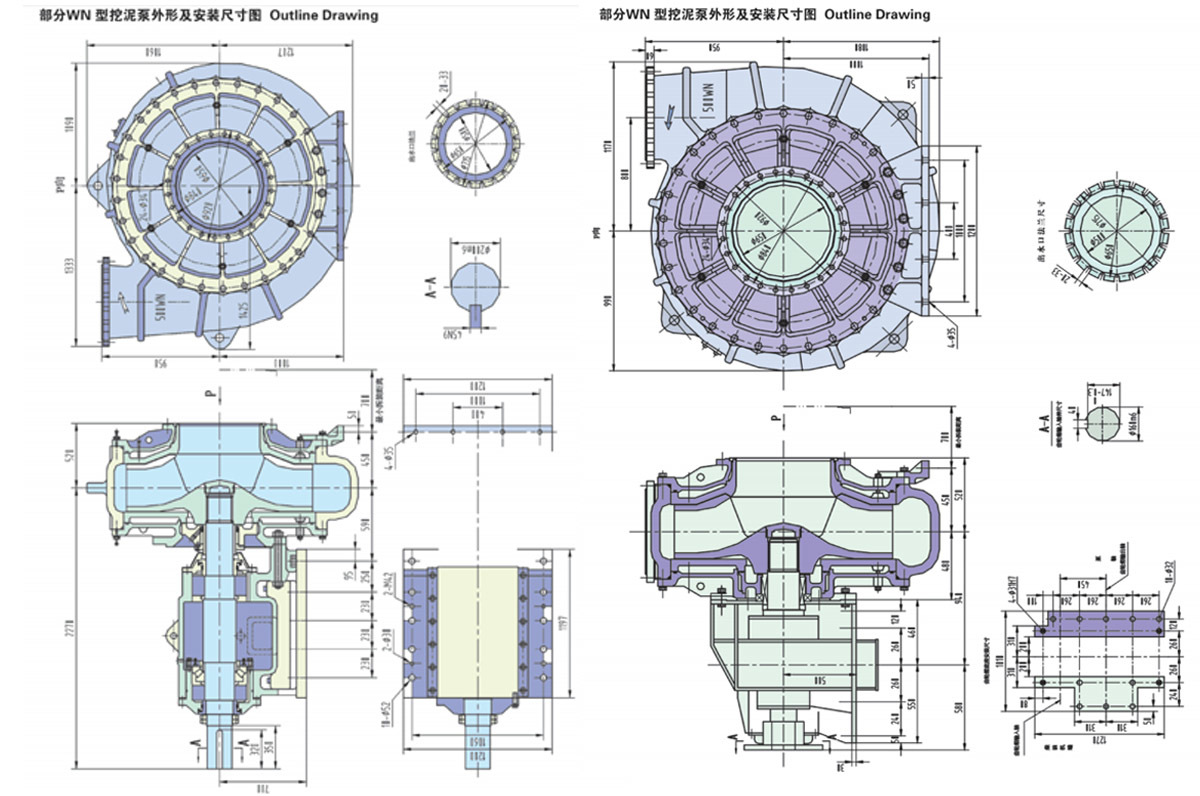

WN Series Dredging Pump

Keywords:

Classification:

Dredge Pump

Product details

Product overview

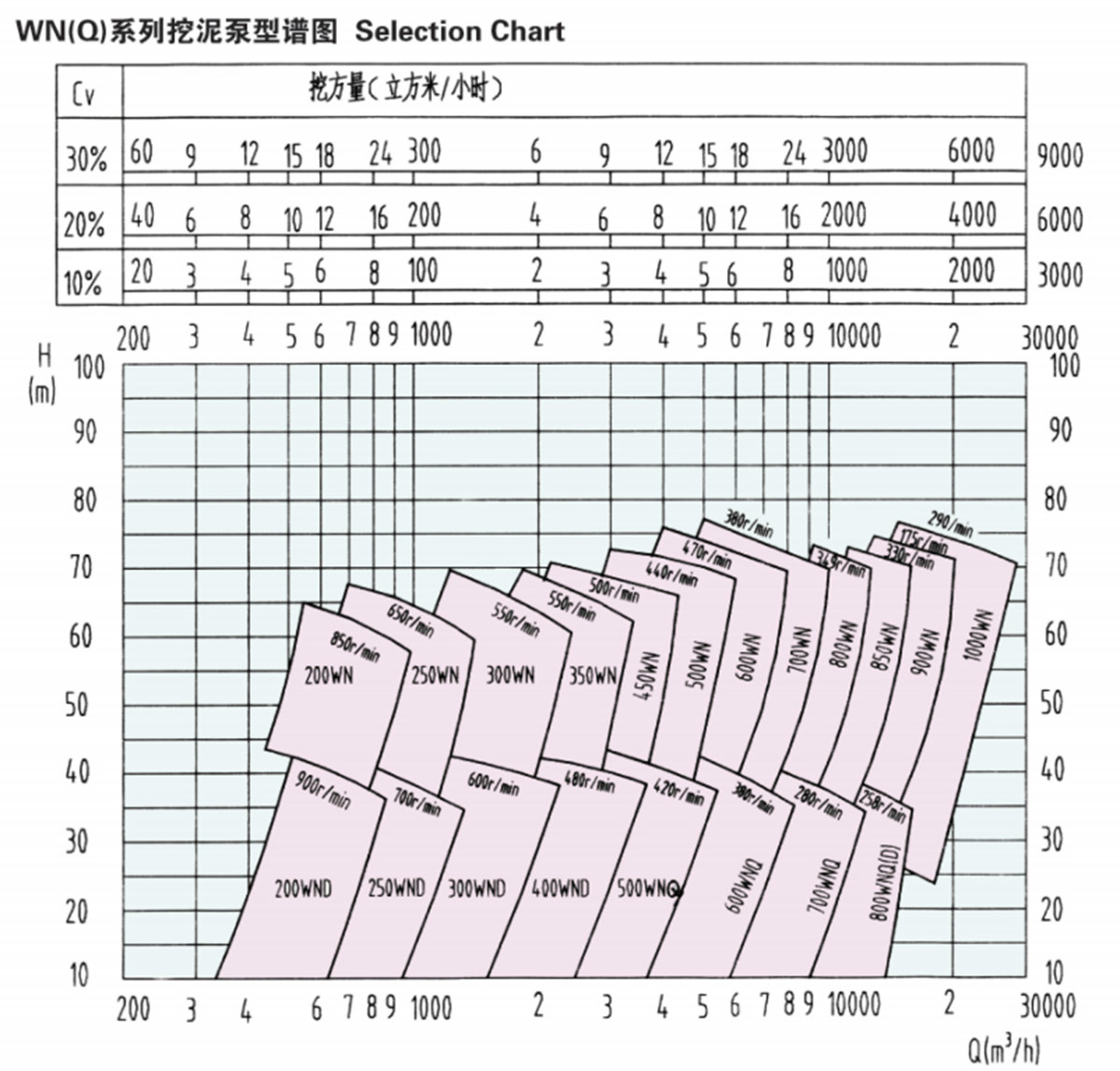

WN(Q) type dredging pump is an efficient and wear-resistant Marine dredging pump developed on the basis of digesting and absorbing the introduction of foreign technology, aiming at the situation that the river dykes at home and abroad are in disrepair and the dredging and filling work is imminent.

The overall structure of the ship is good:

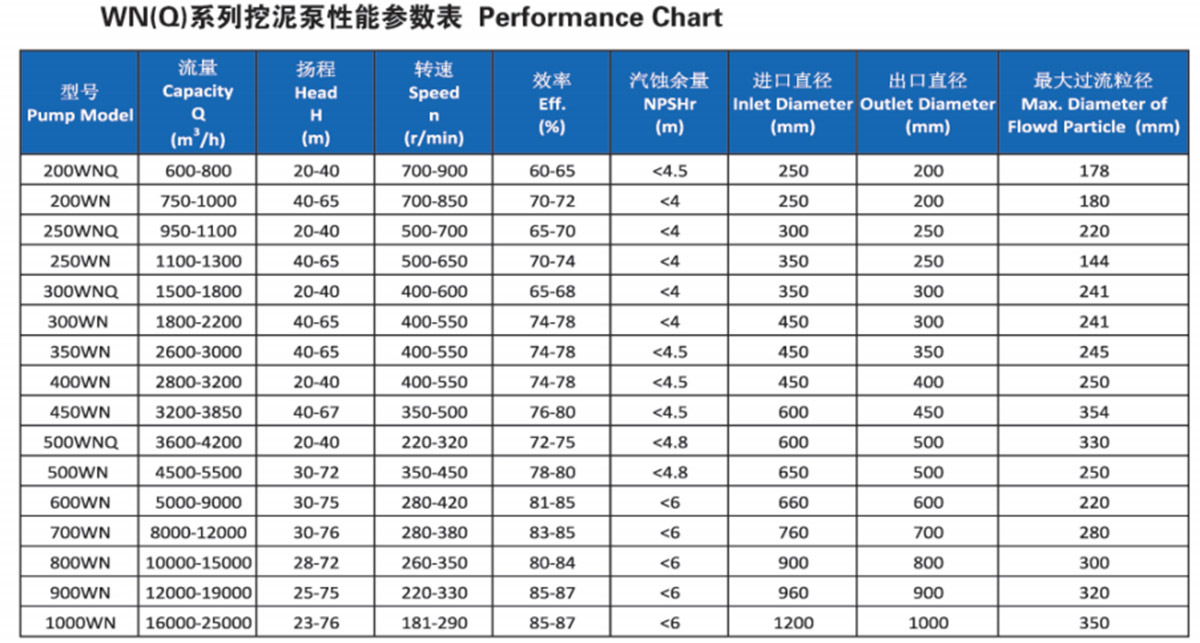

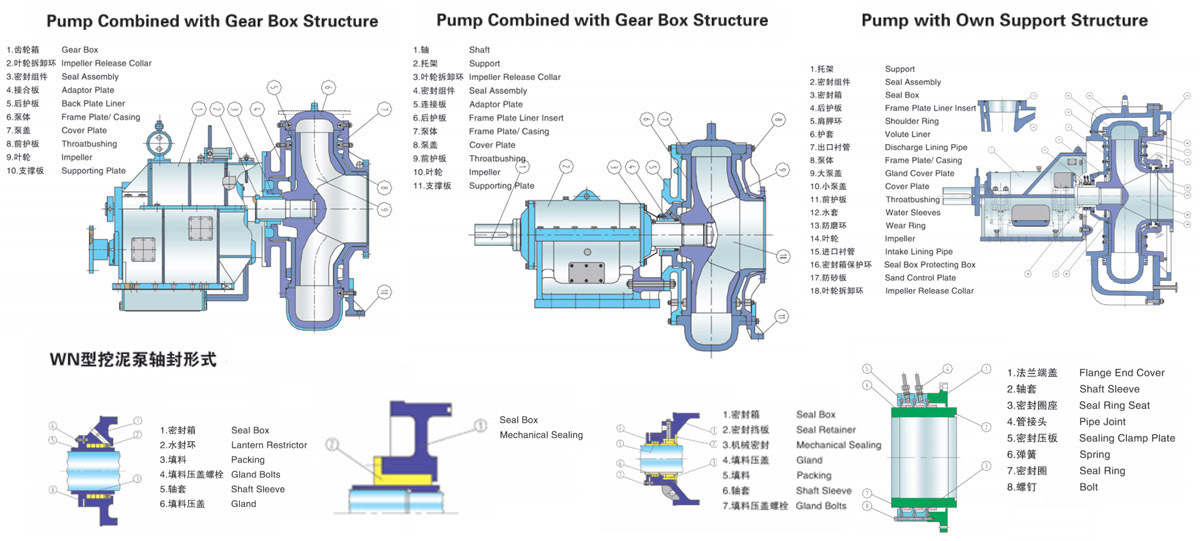

Simple and reliable structure :200WN-500WN, 600WNQ-1000WNQ type dredging pump adopts single pump shell or double pump shell, single stage single suction cantilever horizontal structure, according to the connection with the gearbox can provide two typical structures, that is, with bracket type and pump box in one.

The built-in bracket type lubrication method is grease lubrication or thin oil lubrication. The safety design of the double pump housing allows the jacket to be used until worn out and does not flood the pump compartment when the jacket breaks. Easy disassembly, easy maintenance :WN type dredging pump adopts the front disassembly structure, simple disassembly, facilitate maintenance.

Excellent dredging performance:

1. Good cavitation performance :WN type dredging pump has good cavitation performance to ensure that the suction capacity of the dredging pump is strong, while achieving greater digging depth and higher inhalable concentration

2. Strong flow capacity and wide applicability :WN type dredging pump impeller channel width is large, mud pump itself good passing capacity is a good guarantee of dredging performance range can be continuously pumped gravel or high-speed clay without blockage.

3. Steep drop in performance curve: The flow and head curve of WN type dredging pump drop sharply, making the mud pump more adaptable to changes in row distance.

4. Can achieve a variety of pump performance deployment, WN type dredging pump can change the pump head under the same flow rate by changing the speed of the impeller, or changing the diameter of the impeller of the mud pump.

Good wear resistance, long life of overflow parts:

1. In the flow parts of WN type mud pump, the impeller, sheath, front and rear guard plate (wear-resistant lining plate) are made of strong anti-wear alloy cast iron, the hardness is not less than 58HRC, which has a strong impact resistance, but also has a high degree of abrasion resistance.

2. In the product design process, fully consider the service life matching between parts, and the replacement cycle of wear-resistant parts is basically the same, reducing the maintenance and replacement costs. Low hydraulic loss, high efficiency, low power consumption: Due to the use of advanced hydraulic models, the efficiency level of dredging pumps is high. The efficiency level of WN type dredging pump is 2-3 percentage points higher than that of imported dredging pump on average. In this way, lower fuel consumption can be obtained at the same output.

Reliable shaft seal, no leakage:

1.200WN-500WN type dredging pump shaft seal adopts mechanical seal or packing seal or mechanical seal plus packing compound seal

2.600WN(Q)-1000WN(Q) type dredging pump shaft seal adopts spiral sleeve L-shaped rubber sealing device, which is composed of 3 L-shaped sealing rings and 1 shaft sleeve with special thread.

Recommended Products

SX(R)/SH/SM(R) Series Slurry Pump

SPH Series Heavy Duty Slurry Pump

SH Series Heavy Duty Slurry Pump

Product Consultation

If you are interested in our product, please leave your email and we will contact you as soon as possible. Thank you!