SV, SVR Series Vertical Slurry Pump

Keywords:

Classification:

Vertical Slurry Pump

Product details

Product introduction

SV Series Pump: Impeller, pump body, guard board,bracket, and shaft are made of metal material.

SVR Series Pump: Impeller, pump body, guard board,bracket, and shaft are made of rubber material.

This pump's shaft seal: No shaft seal.

It is suitable for: conveying submerged, abrasive, coarse particles and high concentration slag slurry in metallurgy, mining, coal, electric power and other industries. Without shaft seal and shaft seal water, it can work normally under the condition of insufficient suction. Such as slurry transportation under immersed liquid in metallurgy, mining, electric power, steel plant and chemical industry.

Structural Features

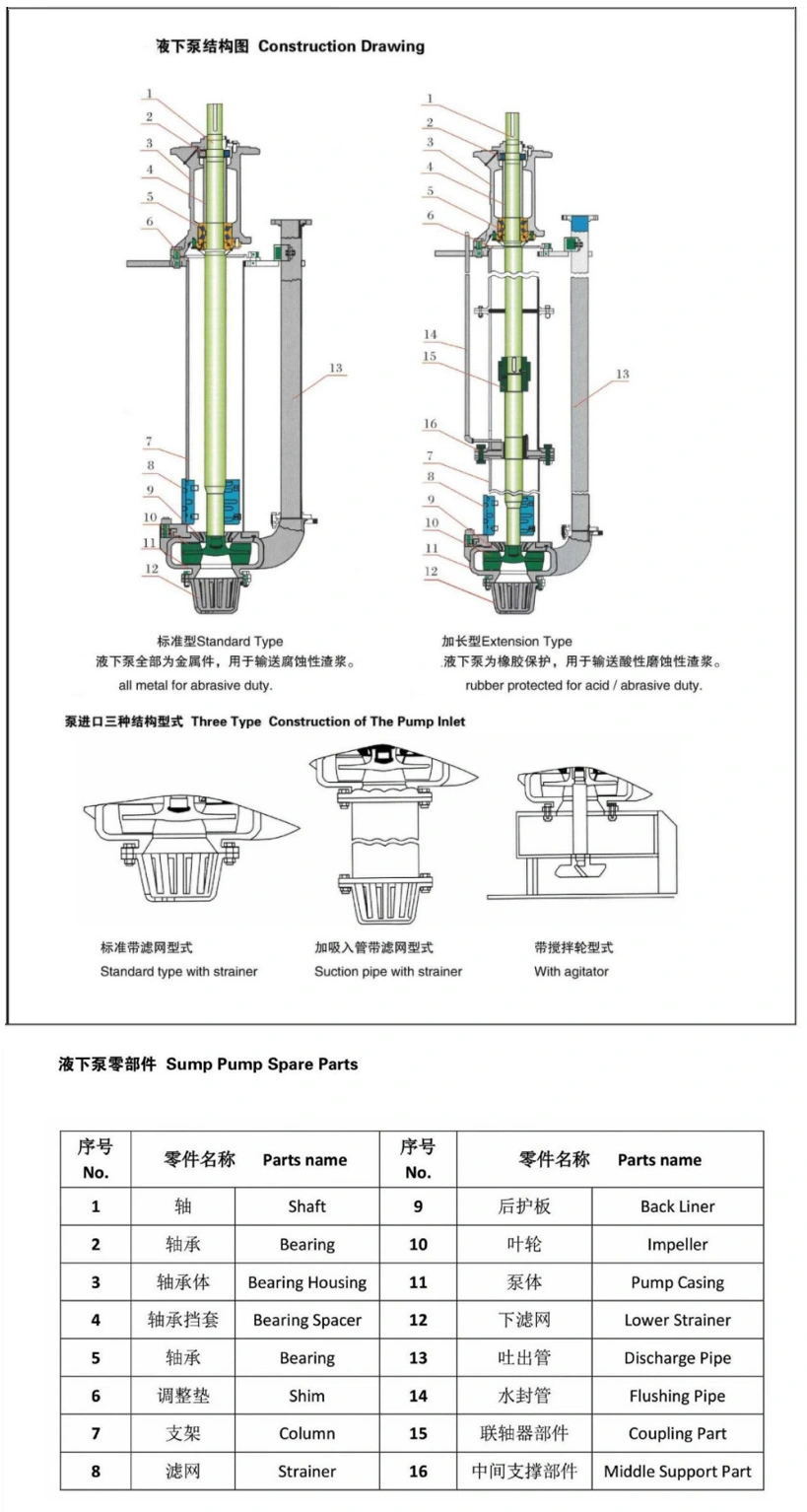

1.The SV slurry pump is a vertical, axial suction, single-stage, single suction, single shell and centrifugal structure.

2.The materials of flow passage parts can be wear-resistant metal or rubber, and the underwater length can be selected according to the needs of users, with simple structure and convenient installation and maintenance.

3.The SV series slurry pump is vertically installed, and the working part is submerged below the liquid level, so no shaft seal is needed. If the pump needs to be used for suction, it is recommended to use the SV impeller and guard plate. Some pumps at the inlet end can be equipped with agitators.

4.The pump motor is arranged above the ground, and the working part of the pump is arranged below the liquid level.

5.The pump shaft can be partially extended according to actual conditions to meet different working conditions.

6.The rotor part adopts vinegar lubrication, and an oil nozzle is set up outside for convenient maintenance.

7.The pump is small in size and light in weight, with a simple structure, easy disassembly, simple maintenance for workers, and can save a lot of labor.

8.The over-flow parts are made of various metal materials, which have good wear resistance and corrosion resistance. The wear rate of the product is low, and as the over-flow parts wear, the overall efficiency declines slowly and smoothly. The rubber pump covers a diameter of 40~150mm.

Production capacity

The total design and production capacity of our factory is 10,000 units (sets) per year, and we can produce 2,000 tons of various high-chromium alloy castings annually. The production area currently includes the following production zones. Namely:casting workshop, heat treatment workshop, machining workshop, metal forming and welding workshop,assembly and painting workshop, spare parts warehouse and finished parts warehouse; Two centers:quality inspection and analysis center and the overall hydraulic test center.

Our products are mainly made of high-chromium wear-resistant white cast iron such as A05, A07, A49, A33, etc. The product development and process formulation all adopt CFD and CAPP new technologies. All castings use resin sand molding and newly introduced lost foam casting technology, which can pour 8-10 tons of castings at one time. The heat treatment workshop has two 20 cubic electric resistance heat treatment furnaces, and the machining shop has two large vertical lathes of 4.2M and 4.5M and more than 20 other types of machine tools. In addition,there are various types of hoisting equipment,metal cutting and welding equipment,impeller level tuning equipment,molding equipment,sandblasting polishing equipment.

Our main products includes a full range of slurry pumps, desulfurization pumps, gravel pumps, dredging pumps, foam pumps, chemical process pumps, PU rubber slurry pumps, and other dozens of varieties, hundreds of models.Widely used in mining (mineral processing), metallurgy, coal, power plant, flue gas desulfurization, silt dredging, sewage treatment industries, chemicals, municipal and environmental protection and so on.

Recommended Products

SX(R)/SH/SM(R) Series Slurry Pump

SPH Series Heavy Duty Slurry Pump

SH Series Heavy Duty Slurry Pump

Product Consultation

If you are interested in our product, please leave your email and we will contact you as soon as possible. Thank you!