SL、SM Light Abrasion Series Slurry Pump

Keywords:

Classification:

Light Duty Slurry Pump

Product details

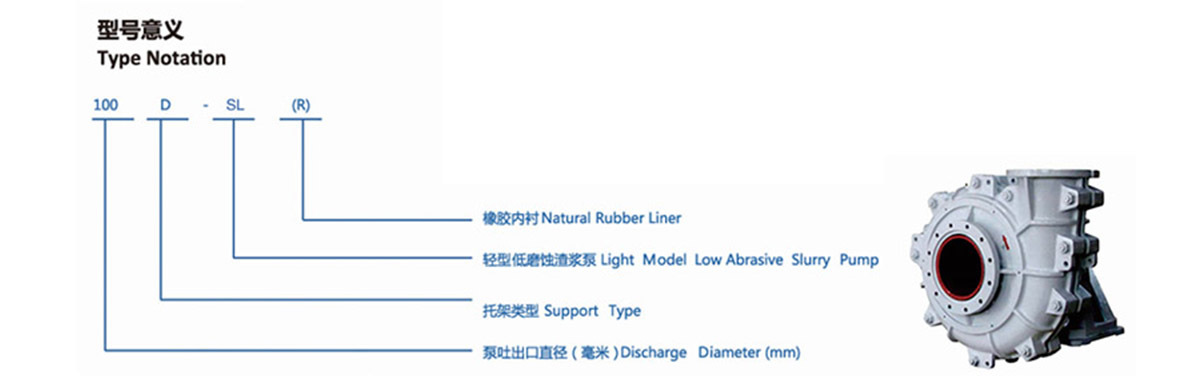

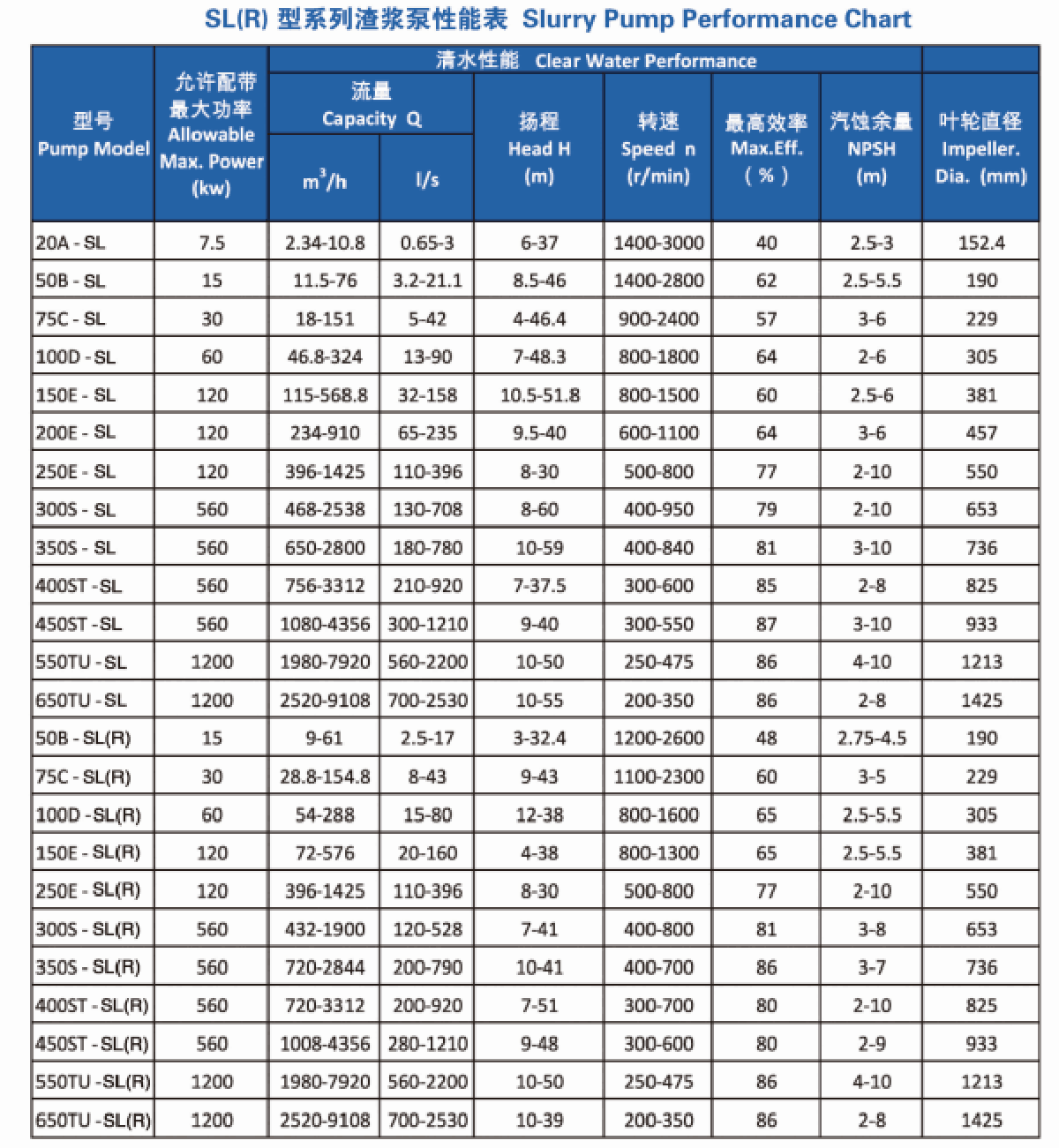

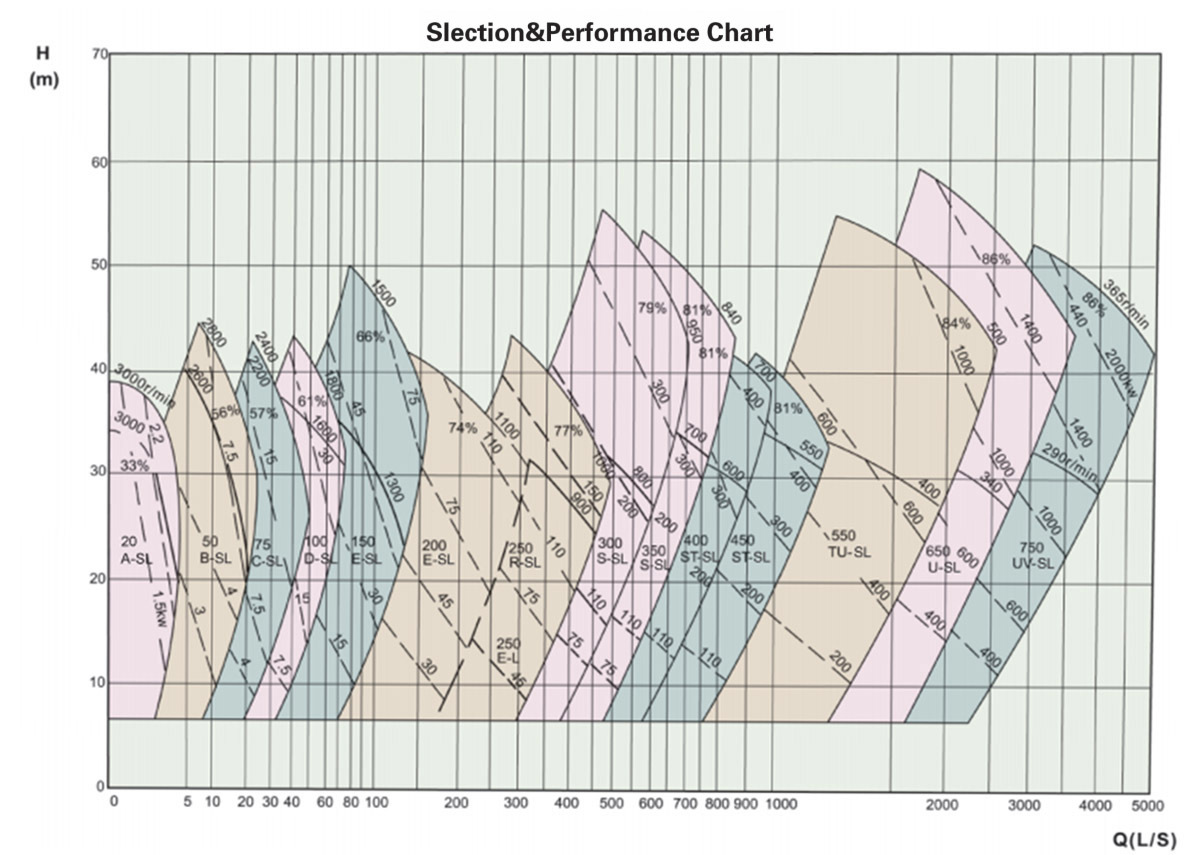

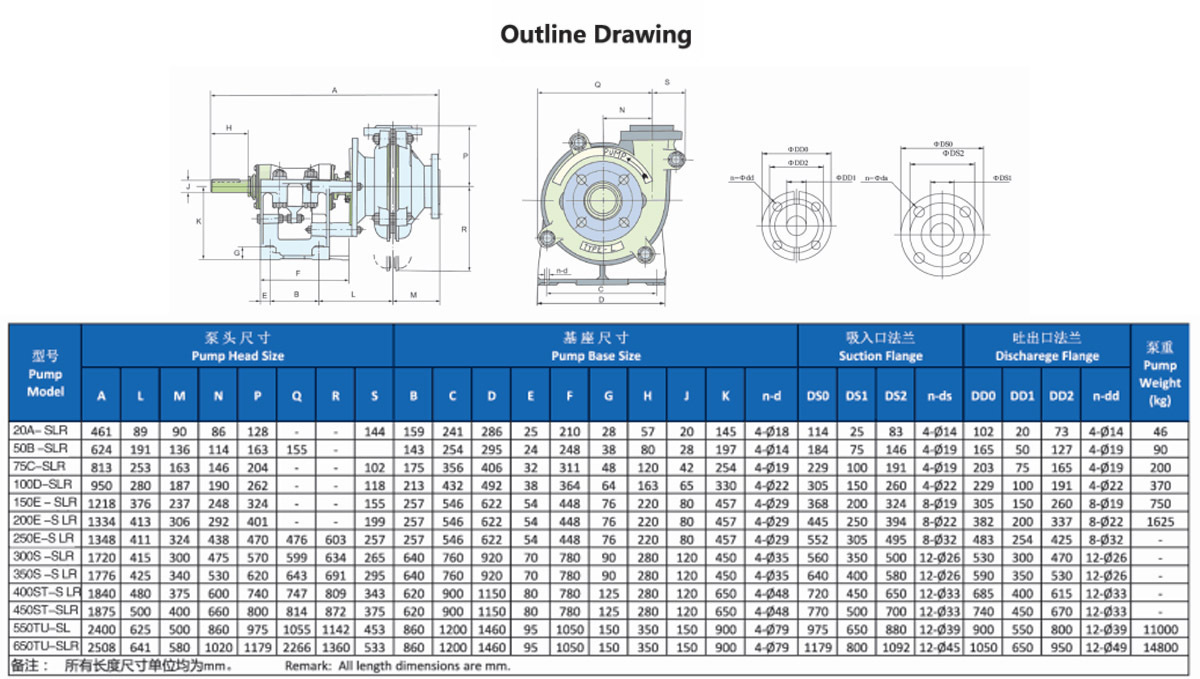

SL(R) type pump is a cantilever, horizontal centrifugal slurry pump, also known as light slurry pump, suitable for metallurgy, mining, coal, building materials and other industrial sectors to transport low abrasive low concentration slurry. The shaft seal of this type of pump can adopt the form of packing seal, impeller seal and mechanical seal.

This type of pump has the advantages of high speed, small size, light weight, and can save floor space. It is suitable for conveying slurry containing fine particles, and the weight concentration of the slurry is generally not more than 30%. The pump has a replaceable wear-resistant metal lining or rubber lining, and the impeller is made of wear-resistant metal or rubber material.

Recommended Products

SX(R)/SH/SM(R) Series Slurry Pump

SPH Series Heavy Duty Slurry Pump

SH Series Heavy Duty Slurry Pump

Product Consultation

If you are interested in our product, please leave your email and we will contact you as soon as possible. Thank you!